-

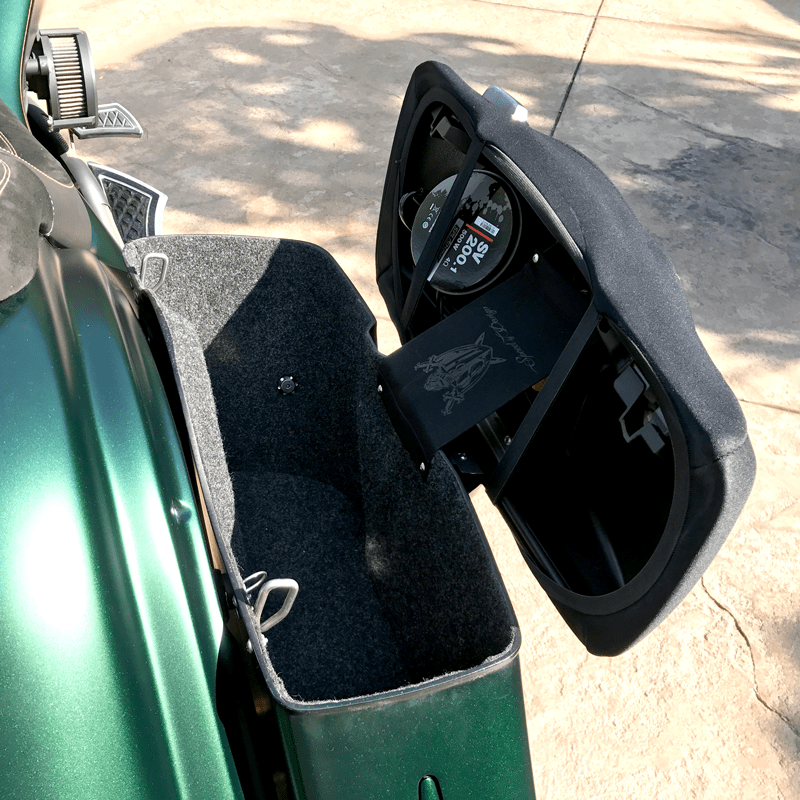

Harley-Davidson Molly Whopper 8″ Speaker Lids

Vendor:Speed By Design8" Harley Davidson Speaker Lids These 8 inch speaker lids fit Harley-Davidson 2014 - Current Touring Models. They are manufactured with urethane injection for professional-grade durability. *Important* – Grills and speakers not included, but check out our speaker package deals! Current Lead Time: 6-8 Weeks Options: We recommend the Hertz SV 200 NEO Speaker. Grills available in Black Powder Coat or Raw. Note: All holes come pre-drilled. Audio Solutions to Elevate Your Aesthetics Make your bike sound as bold as it looks with the Harley-Davidson Molly Whopper 8″ Speaker Lids by Speed By Design. These custom speaker lids are built to turn heads and turn up the volume, giving your ride a seamless blend of form and function. The Molly Whoppers deliver aggressive audio and sleek style that complements any custom audio setup. Designed for Easy Fitment with Speakers and Grills Skip the hassle and get straight to the fun. The Molly Whopper Lids are precision-molded for seamless integration with most 8” audio speakers and matching grills. Each lid is engineered to install easily and securely, making it the perfect upgrade for riders who want to boost sound without spending hours in the garage. Just pair with your favorite speakers, and you’re ready to roll. Compatible with 2014–Current Harley-Davidson Models Whether you ride a Street Glide, Road Glide, or Road King, these new lids are a drop-in speaker upgrade with a factory-like fit. Built specifically for 2014 and newer Harley Davidson touring models, these new lids are built to utilize the brand’s one touch latches to integrate effortlessly with your stock or custom bags. No guesswork, no modification, just perfect compatibility and even better performance. Long-Lasting Durability for Hard-Hitting Endurance These lids are built for the road ahead. Molded from tough materials designed to take a beating, they can handle high-volume audio, harsh weather, and rough rides without cracking, warping, or losing their edge. When you choose Molly Whoppers, you're investing in body parts with long-term durability, so you can keep the sound cranked and the miles piling up. Trust Speed By Design for Top-Quality Products Speed By Design is a name riders trust for next-level quality parts for audio systems. With expert craftsmanship, clean styling, and road-tested resilience, they deliver on every bagger upgrade. At Garage Bagger Stereo, we’re proud to offer these high-performance lids and hardware as part of our hand-picked collection for serious audio enthusiasts. View Garage Bagger Stereo’s full collection of high-performance hardware from Speed by Design. Modification may be required Body part sales are final -

Speed By Design - Copy Cat Killer Lids 98-13 Harley Davidson

Vendor:Speed By DesignSpeed By Design - Copy Cat Killer Lids 98-13 Harley Davidson Speed By Design’s new Copy Cat Killer Lids originated from our original Crazy 8 Lids. We have removed the fin and added the option of running a horn. The new lid is designed to utilize the Hertz ST 35 horn. However, if you would like to run the ST 25, it will also fit!Quality and finish! Just know that we have made lids like these before. Our tooling and manufacturing process remains the same. The new lids will fit and function 100% properly and have the same quality and finish you can always expect from Speed By Design. The Copy Cat Killer Lids with 8-inch Hertz SV 200.1 Speakers and ST 35 or ST 25 horn… They will be the best-sounding lids on the market. Includes: Fits 1997 TO 2013 Models *Important* - Grills, Speakers, and tweeters are not included, but you can order with your choice of speakers. Call us direct 864-334-6131 Manufactured by process of Urethane Injection All lid sales are FINAL Current Lead Time before shipping 4-6 weeks Modification may be required Body part sales are final -

Speed By Design 866 Dope Daddy Speaker Lids (bond on)

Vendor:Speed By DesignHarley Speaker Lids Bond On for SBD Dope Daddy Rear End 8″ & 6″ Speaker lids for the Dope Daddy Rear End Only Each lid fits (1) 6″ and (2) 6.5″ pro audio speakers and will take up to (2) 35mm horns. We recommend the Slick Rick Grills for this product. Sold in Pairs Custom Order parts 4-6 week lead time Modification may be required Body part sales are final -

Speed By Design Big Bass Port

Vendor:Speed By DesignBig Bass Port for your Saddle Bags New Big Bass Bag Ports! Tunable on the fly! These can be installed after paint without gluing bonding or body working. Achieve the bass you are looking for with our tunable Big Bass Bag Ports Easy to change the length and or remove and retune! *** SOLD INDIVIDUALLY *** Please note this part is currently 2-3 weeks out due to parts issues -

Sale

Speed By Design Copy Cat Killer Lids and Hertz Pro Audio Bundle

Vendor:Speed By DesignSpeed By Design Copy Cat Killer Lids and Hertz Pro Audio Bundle The FAMOUS Speed By Design Copy Cat Killer Lids fit Harley Davidson models 98-13. Kit Includes; 1 Pair of Speed By Design Copy Cat Killer Lids 1 Pair Hertz SV200.1 Pro 8" Drivers 1 Pair Hertz ST35 Pro Neo Horns 1 Pair XEL Custom 8" Grillz Black All lids sales are FINAL Current Lead Time before shipping 6-8 weeks on lidsSale -

Speed By Design Dope Daddy Rear End (Drop Rail)

Vendor:Speed By DesignSpeed By Design Dope Daddy Rear End (Drop Rail) These bags take our NEW proprietary longer lids that take an 8 and two 6.5s in each lid, the bags are 8 inches down and extend approximately 4 inches farther back in the lid opening and same at the ground. They are 9 1/4 inches at the widest point for more air space and mounting depth! Our goal was to make a long sexy bag with more air space than the others. Longer looks better than wider. Options: Lids, drop rails with or without battery mount or no drop rail, bag seals, ports, lights, side covers, additional multi layers of fiberglass and we also have second set of lids dropping in January. Proudly meeting all SOS and Sound Bullies criteria Light Weight to Heaven Weight. AVAILABLE OPTIONS 8″ Dope Daddy Side Covers (option) 8 down 15 back Speaker Lids – Available ONLY with our New Rear End! (option) Drop Rail Kit (option) Battery Box (option) Requires Drop Rails (option) Will not take a standard bolt on lid No speaker rings included bags are a blank canvas These bags are not a bolt on kit. Expert installation suggested Shipping cost at checkout is estimated. Final cost will be paid before item ships. Expect to be an average shipping of $300-$500 for the entire kit Current Lead Time 6-8 weeks Modification may be required Body part sales are final -

Speed By Design Funky 8 Tour Pak Lid

Vendor:Speed By Design2014 up Funky 8 Tour Pak Lid 14 up tour pak lid only Holds 2-8" and 2-Horns (audio not included) Spice it up with some killer grills (call for details 864-334-6131 x1) Product was designed to fit the 2014 or newer tour pack Don't have a 14 up Pak, call us we can help you get what you need Complete bottom and top starting at $690 plus the ride, call for details Custom order part all sales are FINAL Current lead time 10-20 business days minimum, HOT NEW Products! New add accessories for the pak Jimmy Cover Water and Scratch Resistant $149.00 Back Rest Seat Pan ( needs to be covered) $49.00 To add the new accessories to your order give us a call 864-334-6131 -

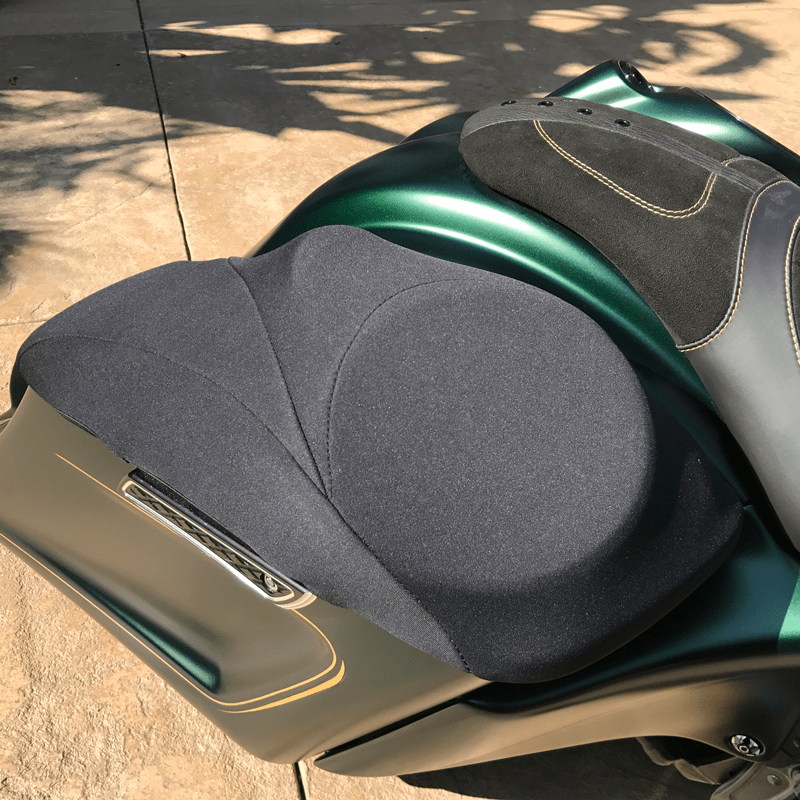

Speed By Design JIMMY COVERS (Pair) - Speaker Lid Covers

Vendor:Speed By DesignWater Resistant Speaker Lid Covers Protect your Harley motorcycle speakers from scuffs, scratches, road debris and water with these speaker lid covers! These Harley Davidson saddlebag speaker lid covers are smooth, soft, and very easy to install. They are both water and scratch resistant, and made with high quality Neoprene which is known to be abrasion, tear, oil and weather resistant! Whether you want to hide those battered saddlebag lids or simply protect your Harley speakers, these speaker lid covers are the way to go. Current lead time 2-3 weeks -

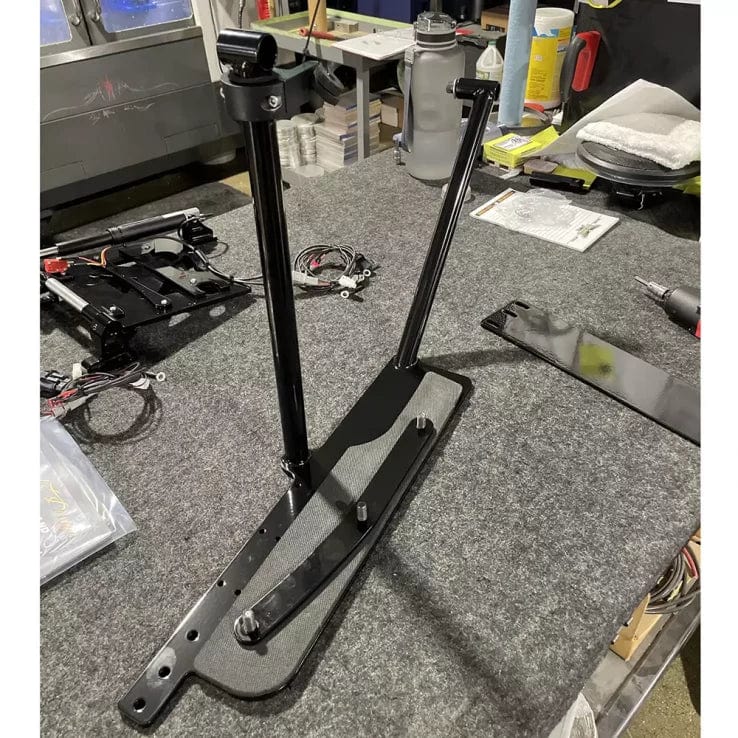

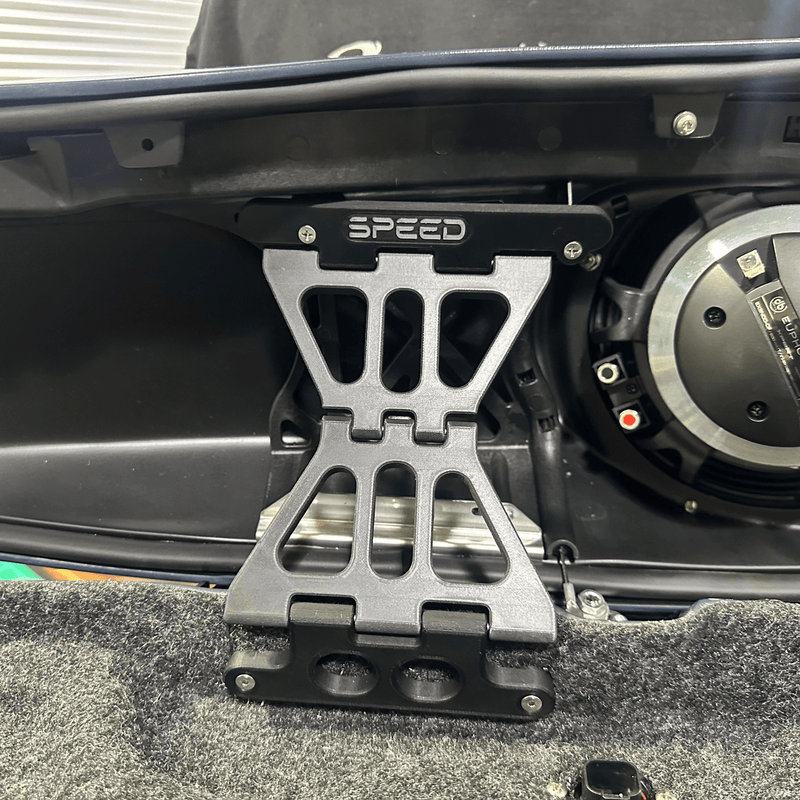

Speed By Design No Drama Lid Stoppers (Pair)

Vendor:Speed By DesignSpeed By Design NO DRAMA LID STOPPERS *Does not work with Advan Black 6×9 Speaker Lids* The innovative No Drama Lid Stopper replaces traditional lid tethers on 2014 and newer style lids while enhancing your saddle bag’s interior appearance. Sold as a pair, these products are a game changer in motorcycle audio and saddlebag functionality for serious enthusiasts looking for both form and function. Unique Lid Stoppers for Top Functionality Engineered with durability in mind, the No Drama Lid Stoppers help prevent paint damage caused by the added weight of heavy speakers often installed inside the lids. By keeping saddlebag lids in an upright, vertical position, the No Drama Lid Stoppers eliminate the frustration of sagging, uneven, or unpredictable lid movements. This not only improves the functionality of your saddlebags but also preserves the look of your bike’s paintwork. By reducing stress on both the lids and the body of your saddlebags, these stoppers contribute to the longevity of your motorcycle’s components — a must for any serious rider investing in top-tier modifications. High-Quality Products from Speed By Design Built on founder Coby Klein’s lifelong passion for motorcycles, Speed By Design is proud to use the highest quality parts throughout the design and build process to provide seamless fitment and an unparalleled ride. With a commitment to personalized service, the company not only strives for a 100% satisfaction rate but also aims to save customers time and money by reducing costly bodywork and paint repairs caused by substandard products. Speed By Design continually works hard to develop innovative products for motorcycle enthusiasts, with the No Drama Lid Stoppers being one of their latest game-changing innovations. Offered in Composite or Billet Aluminum This product is available for purchase in two different materials and a range of colors to suit different preferences and styles: Grey Composite with Black Billet Aluminum Raw Billet Aluminum Black Anodize Billet Aluminum Red Anodize Billet Aluminum Gold Anodize This variety ensures that no matter your bike’s look, there’s a lid stopper option to complement your aesthetic while delivering high-level functionality Designed for 2014 & Newer Style Lids The No Drama Lid Stoppers are available for: Non-CVO Motorcycle Models (2014-23) CVO Motorcycle Models (2024-Current) Key Features Works with all 2014 and newer style lids, from stock to audio-filled Prevents paint damage from heavy speakers Keeps lids upright and vertical Replaces traditional, less effective lid tethers Enhances the interior appearance of saddlebags Not compatible with Advan Black 6×9 Speaker Lids Currently, these products carry an estimated lead time of 5-10 business days Explore Garage Bagger’s full collection for more Speed By Design products. -

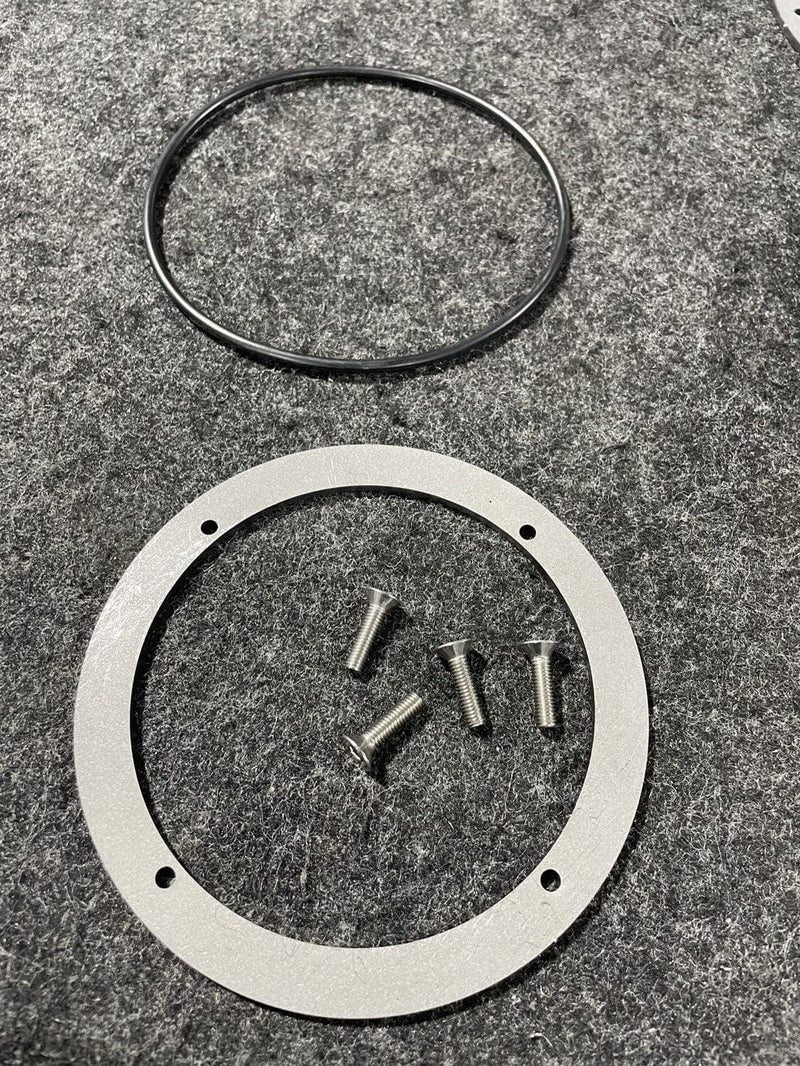

Speed By Design Slick Rick's 8" Grillz

Vendor:Speed By DesignCurrent Lead Time Estimated 4-6 weeks Designed to help protect your speakers, this 8-inch wire mesh speaker grill fits seamlessly with motorcycle audio systems for an enhanced audio experience. This product includes all necessary hardware to mount the grills, helping riders quickly upgrade their systems with minimal hassle. Whether you’re cruising through the city or tearing down highways at high speed, these grills ensure your speakers stay protected and sound their best. Protect Motorcycle Speakers with a Speaker Grill In addition to its visual appeal, a speaker grill can provide significant protection for a motorcycle’s speaker system. They act as a barrier against the various elements that your bike is exposed to on the road, including dirt, dust, debris, and moisture. Slick Rick’s 8" Grillz act as a durable shield, preventing accidental damage from flying debris or unexpected weather conditions. In addition to protecting the audio system, grills help maintain audio quality for a long-term speaker solution. Trusting a high-quality grill can mean fewer repairs, better sound quality over time, and less need for costly speaker replacements. Premium Products from Speed By Design Driven by founder Coby Klein’s lifelong love for motorcycles, Speed By Design is dedicated to using only the highest quality parts in every design and build. From saddlebag accessories to high-performance audio solutions, every product is handled with attention to detail and a true passion for the riding experience throughout the manufacturing process. Committed to personalized service, Speed By Design works to achieve complete customer satisfaction while helping drivers avoid costly bodywork and paint repairs often caused by lower-quality parts. The company continues to innovate, developing advanced products tailored to the needs of motorcycle enthusiasts. Designed around their high-quality Speed By Design speaker lids, Slick Rick’s 8" Grillz are made with precision in-house. Stylish Grill Options with Top Sound Quality Transform your motorcycle’s entire look with a new speaker grill. Installing a speaker grill can enhance the bike’s overall aesthetics with a classic look while providing significant support to the motorcycle audio system. The Slick Rick's 8" Grillz are available in black or raw finish options, allowing riders to tailor the aesthetic to match their personal style or the bike’s existing theme. Besides their stylish appearance, these grills are precision-engineered to maintain optimal sound quality without muffling or distorting audio performance. Installing a quality speaker grill like Slick Rick’s ensures that your audio stays crisp, clear, and protected. Key Features Includes all necessary hardware for mounting grills Available in black or raw finish options Fits seamlessly over 8-inch speakers for motorcycles Helps maintain top audio quality Currently, these products carry an estimated lead time of 4-6 weeks For more motorcycle audio options, view Garage Bagger’s full collection of Speed By Design products. -

Speed By Design TWISTED 8 Harley Speaker Lids

Vendor:Speed By DesignHarley Davidson 8" Speaker Lids 6-8 Week Lead Time Speed By Design’s new Twisted 8 Speaker Lids originated from our Loud Daddy Lids which fit 7.7 inch speakers. The main difference between the new speaker lids and Loud Daddy Lids is we have increased the diameter of the speaker insert to 8.2 inches and added the option of running a horn. The new harley speaker lid is designed to utilize Harley Davidson's one touch latches and the Hertz ST 35 horn. However, if you would like to run the ST 25 it will fit as well! Quality and finish! Just know that we have made 8 inch speaker lids like these before. Our tooling and manufacturing process remains the same. The new harley speaker lids will fit and function 100% properly and have the same quality and finish you can always expect from Speed By Design. The Twisted 8 Lids with 8 inch Hertz SV 200.1 Speakers and ST 35 or ST 25 horn. These Harley 8 Inch speaker lids will be the best sounding lids on the market, so take advantage of this motorcycle audio upgrade. You'll be able to add some serious sound to your Harley with a set of these on your saddlebags. Fitment: 2014 and up current models - Harley Davidson Road Glide, Street Glide, and more. All lids are raw material will need to be baked if possible, body worked and painted. These do not come show room finished.All body parts sales are final no returns. Grills, speakers, and tweeters are not included. Want them LOADED with speakers and grills? Call the shop 864-334-6131 or contact us. All lid sales are FINAL -

Speed By Design Twisted8 Lids and Cicada Audio LOADED Bundle

Vendor:Speed By DesignThe FAMOUS Speed By Design Twisted8 Lids, fits Harley Davidson models 14-current, loaded with Kit Includes; 1 pair Cicada 8" mid bass available in 2Ω or 4Ω SPECS: 500WRMS/1000 MAX Power Handling- PAIR Frequency Response: 75Hz -10Khz+/-5dB Neodymium High Energy/ Light Weight N35 Magnet structure Heavy Duty / Die-cast Aluminum Basket 2.0” 2Ω or 4Ω / High Temp Voice Coil (Black Coat™) Voice Coil MidBass Shortening Ring for the Ultimate in speaker control Advanced Voice Coil Heat Sink Design for Better Heat Dissipation High Sensitivity: 94dB / 99dB 1W/1M Average (1W/1M – 2.83V) Total Diameter: 8.3” / 210.5mm Mounting Diameter: 7.1” / 180mm Mounting Depth: 3.6” / 91.2mm SOLD IN PAIRS Weather treated 1 pair of Cicada Ring Radiator Horn Speaker SPECS: 100WRMS/400 MAX Power Handling- PAIR Frequency Response: 2Hz -20Khz+/-5dB Neodymium High Energy/ Light Weight N35 Magnet structure Heavy Duty/ Die-cast Aluminum Basket 4 Ohm for increased durability V9 Phase Plug for increased Dispersion and Increased Sound Quality (a Cicada Exclusive!) 1.0” Aluminum Diaphragm High-Temp Voice Coil for Tweeter Advanced Voice Coil Heat Sink Design for Better Heat Dissipation High Sensitivity: 107dB 1W/1M Average (1W/1M – 2.83V) 12dB Crossover with custom tooled/ Vented crossover case Choice of Grills 1 Pair XEL 8" Black or 1 Pair of SBD Slick Rick Black or 1 Pair Advan Black Contrast CNC Aluminum Grills 10-15 business day lead time Modification may be required Body part sales are final

-

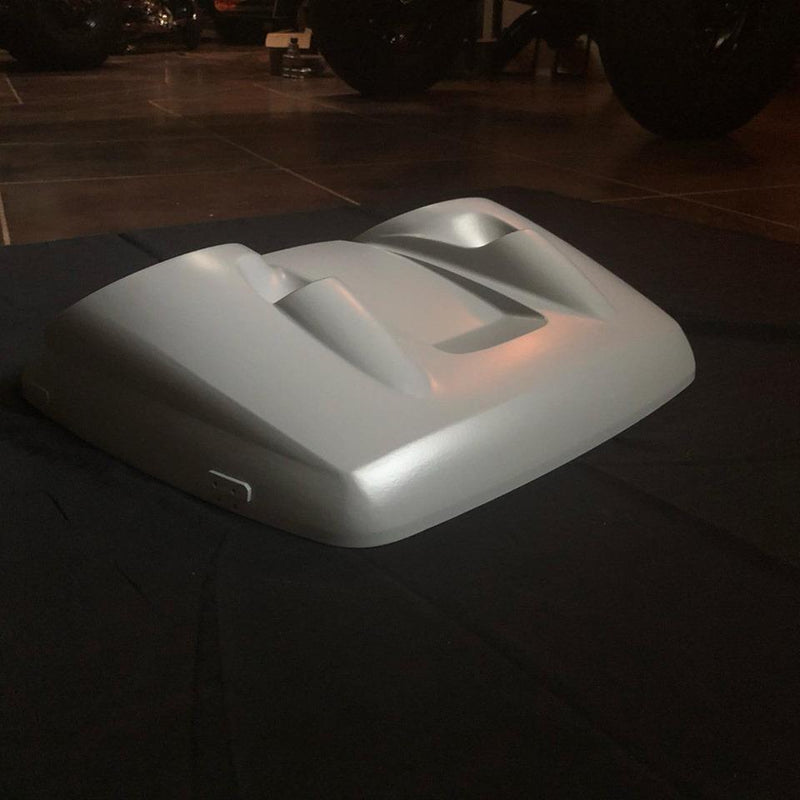

Harley-Davidson Molly Whopper 8″ Speaker Lids

Vendor:Speed By Design8" Harley Davidson Speaker Lids These 8 inch speaker lids fit Harley-Davidson 2014 - Current Touring Models. They are manufactured with urethane injection for professional-grade durability. *Important* – Grills and speakers not included, but check out our speaker package deals! Current Lead Time: 6-8 Weeks Options: We recommend the Hertz SV 200 NEO Speaker. Grills available in Black Powder Coat or Raw. Note: All holes come pre-drilled. Audio Solutions to Elevate Your Aesthetics Make your bike sound as bold as it looks with the Harley-Davidson Molly Whopper 8″ Speaker Lids by Speed By Design. These custom speaker lids are built to turn heads and turn up the volume, giving your ride a seamless blend of form and function. The Molly Whoppers deliver aggressive audio and sleek style that complements any custom audio setup. Designed for Easy Fitment with Speakers and Grills Skip the hassle and get straight to the fun. The Molly Whopper Lids are precision-molded for seamless integration with most 8” audio speakers and matching grills. Each lid is engineered to install easily and securely, making it the perfect upgrade for riders who want to boost sound without spending hours in the garage. Just pair with your favorite speakers, and you’re ready to roll. Compatible with 2014–Current Harley-Davidson Models Whether you ride a Street Glide, Road Glide, or Road King, these new lids are a drop-in speaker upgrade with a factory-like fit. Built specifically for 2014 and newer Harley Davidson touring models, these new lids are built to utilize the brand’s one touch latches to integrate effortlessly with your stock or custom bags. No guesswork, no modification, just perfect compatibility and even better performance. Long-Lasting Durability for Hard-Hitting Endurance These lids are built for the road ahead. Molded from tough materials designed to take a beating, they can handle high-volume audio, harsh weather, and rough rides without cracking, warping, or losing their edge. When you choose Molly Whoppers, you're investing in body parts with long-term durability, so you can keep the sound cranked and the miles piling up. Trust Speed By Design for Top-Quality Products Speed By Design is a name riders trust for next-level quality parts for audio systems. With expert craftsmanship, clean styling, and road-tested resilience, they deliver on every bagger upgrade. At Garage Bagger Stereo, we’re proud to offer these high-performance lids and hardware as part of our hand-picked collection for serious audio enthusiasts. View Garage Bagger Stereo’s full collection of high-performance hardware from Speed by Design. Modification may be required Body part sales are final -

Speed By Design - Copy Cat Killer Lids 98-13 Harley Davidson

Vendor:Speed By DesignSpeed By Design - Copy Cat Killer Lids 98-13 Harley Davidson Speed By Design’s new Copy Cat Killer Lids originated from our original Crazy 8 Lids. We have removed the fin and added the option of running a horn. The new lid is designed to utilize the Hertz ST 35 horn. However, if you would like to run the ST 25, it will also fit!Quality and finish! Just know that we have made lids like these before. Our tooling and manufacturing process remains the same. The new lids will fit and function 100% properly and have the same quality and finish you can always expect from Speed By Design. The Copy Cat Killer Lids with 8-inch Hertz SV 200.1 Speakers and ST 35 or ST 25 horn… They will be the best-sounding lids on the market. Includes: Fits 1997 TO 2013 Models *Important* - Grills, Speakers, and tweeters are not included, but you can order with your choice of speakers. Call us direct 864-334-6131 Manufactured by process of Urethane Injection All lid sales are FINAL Current Lead Time before shipping 4-6 weeks Modification may be required Body part sales are final -

Speed By Design 866 Dope Daddy Speaker Lids (bond on)

Vendor:Speed By DesignHarley Speaker Lids Bond On for SBD Dope Daddy Rear End 8″ & 6″ Speaker lids for the Dope Daddy Rear End Only Each lid fits (1) 6″ and (2) 6.5″ pro audio speakers and will take up to (2) 35mm horns. We recommend the Slick Rick Grills for this product. Sold in Pairs Custom Order parts 4-6 week lead time Modification may be required Body part sales are final -

Speed By Design Big Bass Port

Vendor:Speed By DesignBig Bass Port for your Saddle Bags New Big Bass Bag Ports! Tunable on the fly! These can be installed after paint without gluing bonding or body working. Achieve the bass you are looking for with our tunable Big Bass Bag Ports Easy to change the length and or remove and retune! *** SOLD INDIVIDUALLY *** Please note this part is currently 2-3 weeks out due to parts issues

Quality Materials for a Long-Lasting Fit

Speed By Design products are crafted from the highest quality materials built to withstand long rides, tough weather, and the wear-and-tear of high speed and low speed use. Whether you're cruising cross-country or upgrading your weekend setup, you can count on a secure, custom fit that holds up mile after mile.

Built for Consistent Durable Performance

Reliability on the road starts with parts you can trust. Audio mounts, speaker lids, and hardware from Speed By Design are engineered to deliver consistent results ride after ride. This is equipment built for clean audio and a solid foundation for your sound system. Invest in high-performance audio so you can turn up the volume and stay focused on the road ahead.

Distinctive Bagger & Performance Bagger Parts

Speed By Design offers some of the most distinctive products on the market tailored to bagger and performance bagger setups. Popular items like the Twisted 8 and Loud Daddy Speaker Lids bring both aggressive design elements and unbeatable audio projection. Looking for practical enhancements? The No Drama Lid Stopper is a game changer, eliminating unwanted movement and noise and locking your audio lids in place without hassle. These performance-driven upgrades meet the unique needs of Harley-Davidson and similar platforms with expert understanding of the challenges faced on the road.

Top Rider Satisfaction

Speed By Design has been recognized for its innovative products that enhance both performance and riding experience. Customers consistently praise the quality and ease of installation that SBD products deliver. One review noted that the Funky 8 Tour Pak Lid was “ridiculously high quality” and that the “communication with the retailer was second to none.” Garage Bagger Stereo’s expert services offer thorough support to help Baggers with SBD assembly and upgrades.

View Speed By Design Products Available at Garage Bagger Stereo

At Garage Bagger Stereo, we've spent over a decade helping riders upgrade their motorcycle audio systems with confidence. Our team members know the ins and outs of products and installation for a range of models, offering expert guidance and support every step of the way. With quick shipping and exceptional customer support, we take the hassle out of getting the sound you want.

Ready to elevate your ride with professional-grade audio mounting solutions? Reach out to Garage Bagger and hear the difference that professional-grade quality makes.